Pipe bending

FERLIGS offers wide range of pipe bending and further processing. We offer bending of steel, stainless steel, aluminium, as well as chromium-molybdenum steel (25CrMo4) pipes of various thicknesses from 0.7 mm to 4 mm with bending angle up to 180°.

We have the uprated hydraulic pipe bender JDsquared at our disposal allowing us to feed the pipe precisely, observing distances between bends.

Hydraulic pipe bender

- D 20 mm and bending radius *76.2 mm

- D 22 mm and bending radius *88.9 mm

- D 25 mm and bending radius *88.9 mm

- D 32 mm and bending radius *139.7 mm

- D 38 mm and bending radius *139.7 mm

- D 50 mm and bending radius *165.1 mm

Hydraulic pipe bender

- D 20 mm and bending radius *76.2 mm

- D 22 mm and bending radius *88.9 mm

- D 25 mm and bending radius *88.9 mm

- D 32 mm and bending radius *139.7 mm

- D 38 mm and bending radius *139.7 mm

- D 50 mm and bending radius *165.1 mm

By using pipe benders, pipes can be given almost any bending angle (provided that bending radius is at least two pipe radiuses). If pipe benders are not used, and the required geometry of pipe construction is formed by angle pieces and welding, it will significantly reduce robustness of the product.

Company’s policy is directed at improving the technical base and improving the technology, therefore our tooling constantly grows, allowing us to match the customers’ needs.

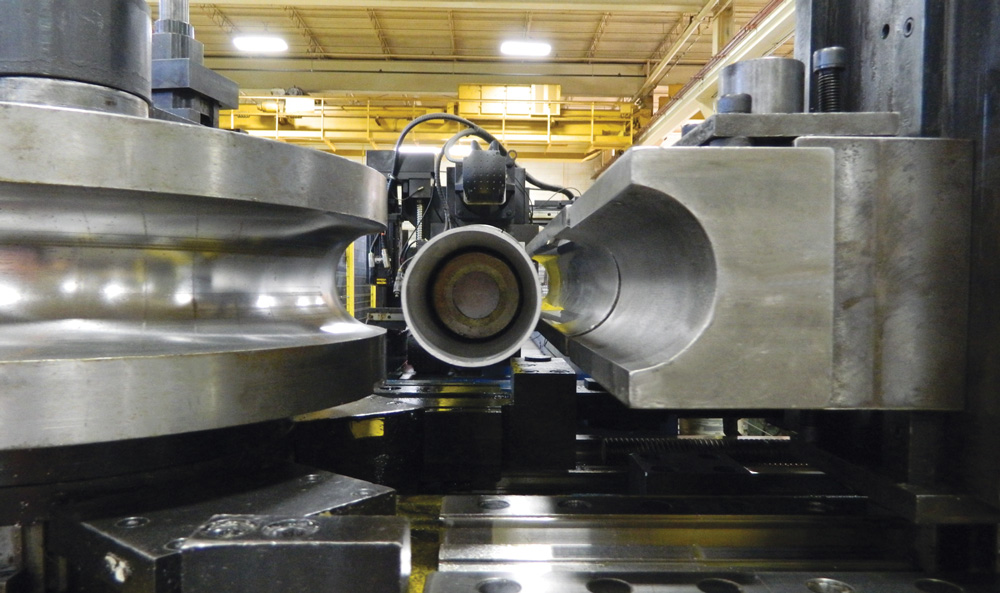

In order to understand, why mandrel pipe bender is necessary, we should understand, how pipe bending proceeds and what is it fraught with.

Mandrel pipe bender

Mandrel pipe bender looks very specific, but is extremely popular in many industries, starting with production of furniture, interior elements, through metal constructions, shipbuilding and to automobile production.

In walls of the section being bended, forces with opposite direction act. Thus, the wall at the inner bending radius starts deforming and corrugation (flute) forms. Product wall at the outer bending radius, on the contrary, stretches and becomes thinner, which frequently results in the wall becoming flat or breaking. These defects mostly appear with thin-walled pipes and small bending radiuses, therefore mandrel pipe bender is essential for work with thin-walled pipes.

We have a semi-automatic mandrel pipe bender at our disposal, allowing us to perform quickly and with high precision not only a single bend, but also series of parts with high repeatability.

Currently, we have matrices and mandrels for the following pipe sizes:

- D 40 mm un liekuma rādiuss 120 mm - tapnis sienas biezumam 1,5 mm

- D 50 mm un liekuma rādiuss 125 mm - tapnis sienas biezumam 2 mm

Please note:

.dxf, .dwg or 3D model (.STEP, .X_T, .STL)

.dxf, .dwg or 3D model (.STEP, .X_T, .STL)

3D model (.SLDPRT, .STEP, .X_T, .STL,)

3D model (.STEP, .X_T,) or (.JPG, .JPEG, .STL)

Drawing requirements:

Scal must be 1:1

All objects has be converted into curves and sizes are in millimetres (mm).

Make sure that file does not have fills, raster images, open and overlaid contours, double lines and dots

The contour of the cut in the file must be displayed in the front view (not in mirrored).

It is desirable to specify text explanations to the order in the file

Additional charge may be applied if file needs rework

Call or email us and we always ready to provide free of charge consultancy on your questions. Our services are not limited only with pipe bending, but we also offer you advertisement, furniture or any other construction assembly.